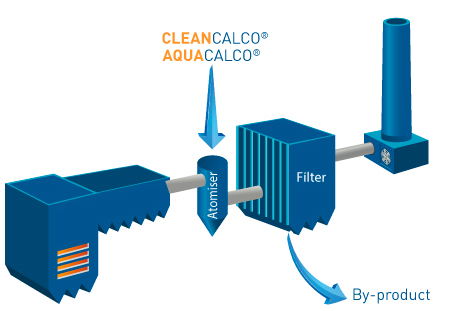

Semi-Wet systems, also called Lime Spray Dryer or Spray Drying Absorber (SDA), consists of the injection of milk of lime, which is a slurry of calcium hydroxide (Ca(OH)2), into the flue gas at the entry of a reactor located in front of the dedusting unit. The temperature of the flue gases should be high enough to totally dry the slurry.

Semi-Wet systems, also called Lime Spray Dryer or Spray Drying Absorber (SDA), consists of the injection of milk of lime, which is a slurry of calcium hydroxide (Ca(OH)2), into the flue gas at the entry of a reactor located in front of the dedusting unit. The temperature of the flue gases should be high enough to totally dry the slurry.

The neutralization of the acid gases starts at the injection point and continues down to the filter. The slurry drying increases the moisture of the flue gas which favours the mitigation of acid pollutants. On the other hand, the injection rate of the slurry is limited by the temperature and the humidity of the flue gases, unlike most of the other processes, which have only one limitation.

Optional recycling of the residues is possible but is not the most widely used configuration. This layout does maximize the reagent utilization however fly-ash recycling can be difficult in the atomizing tower.

Performance of such systems depends on

- Flue gas characteristics such as composition, temperature and humidity

- Quality of the milk of lime

Key Benefits of semi-wet systems with CleanCalco®

- Efficient process

- Dry by-product & no liquid treatment requirement

- Can work with cost-efficient sorbent, our CleanCalco® QL

- Carmeuse expertise to support operation, including reagent preparation outsourcing)

Product range

The reagent preparation is very critical because bad or inconsistent milk of lime properties can lead to high variations in the process efficiency. Depending on the reagent preparation design, Carmeuse can offer

- AquaCalco®, a ready-to-use milk of lime that requires no preparation on the customer side;

- CleanCalco® SD, a calcium hydroxide to be put in suspension;

- CleanCalco® QL, engineered quicklime for on-site slaking units.

Whatever the option chosen, one of the key aspects is the stability of the reagent characteristics in order to have stable milk of lime, and thus a stable efficiency in the flue gas cleaning process. The reagent preparation is the most common step to bring operational issues. Our expert team and partnership vision solves most of the problems through audits, troubleshooting and even outsourcing options (as described in the support section)