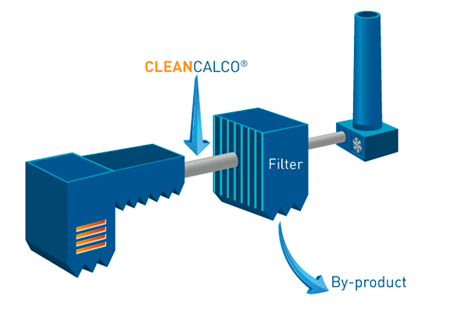

Dry Sorbent Injection (DSI) consists of the direct injection of an alkaline material, typically hydrated lime (Ca(OH)2), into the flue gas before the dedusting unit. The neutralization of acid gas starts at the injection point and continues down to the filter.

Dry Sorbent Injection (DSI) consists of the direct injection of an alkaline material, typically hydrated lime (Ca(OH)2), into the flue gas before the dedusting unit. The neutralization of acid gas starts at the injection point and continues down to the filter.

The location of the injection points is thus very critical as the flue gas characteristics at this point will greatly influence the removal efficiency.

The performance of this system depends on:

- the flue gas characteristics such as composition, temperature and humidity

- the quality of the hydrated lime used as sorbent

- the technology used such as dispersion through the flue gas and location of the injection

Carmeuse has developed a full range of calcium hydroxide (or hydrated lime) products, CleanCalco®, that will fit most applications and adapt to the different conditions within those applications

Key Benefits of the DSI process with CleanCalco® :

- Simplicity

- Ready-to-use reagent

- Minimum equipment required

- Low investment cost, low footprint and low maintenance

- Dry by-product and no liquid treatment requirement

- Flexibility

- Large range of flue gas characteristics (temperature...)

- Compatible with every particulate collector (bag filter, ESP…)

- Can be used with other flue gas treatment systems, as pre-treatment / post-treatment…

Product range

Selection of the right product will maximize the result while minimizing reagent consumption. This selection has to be done case-by-case, together with our experts, depending on your particular case.

- CleanCalco® SD (hydrated lime ready-to-use),

- CleanCalco® FGC (hydrated lime ready-to-use),

- CleanCalco® HSF (hydrated lime ready-to-use),

- CleanCalco® HSF-AC (hydrated lime containing activated carbon ready-to-use),