Sulfur removal is highly influenced by the temperature at which the reaction takes place. Direct injection into the furnace/boiler of an alkaline material, typically hydrated lime (Ca(OH)2) based sorbents or limestone (CaCO3), allows the neutralization of the pollutant.

Sulfur removal is highly influenced by the temperature at which the reaction takes place. Direct injection into the furnace/boiler of an alkaline material, typically hydrated lime (Ca(OH)2) based sorbents or limestone (CaCO3), allows the neutralization of the pollutant.

Key benefits of hot side injection with CleanCalco®

- Simplicity

- Ready-to-use reagent

- Flexibility

- Low stoichiometry

- Compatible with most furnaces/boilers

- Minimum equipment required

- Low investment cost, low footprint and low maintenance

- Dry by-product and no liquid treatment requirement

- Compatible with every particulate collector (filter, ESP…)

- Can be used with other flue gas treatment systems, as pre-treatment

Product range

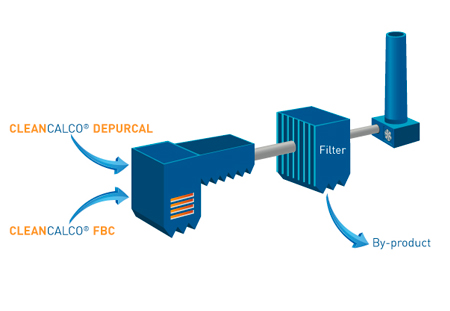

- CleanCalco® Depurcal, a dedicated hydrated lime product injected at high temperatures (>850°C) and particularly active on SOX and HF. This injection allows direct action on the pollutant, offering significant efficiencies at low stoichiometry.

- CleanCalco® FBC is our dedicated limestone for injection in fluidized bed combustor. This in-situ process focused on fluidized bed units is particularly cost efficient for SO2 removal (up to 90%) as no dedicated treatment unit is needed. For highest removal efficiency a downstream polishing Flue Gas Cleaning process is needed