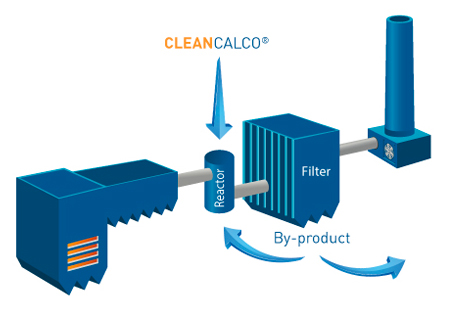

Semi-Dry Flue Gas Cleaning (FGC) consists of the injection of hydrated lime (Ca(OH)2) into the flue gas at the entry of a reactor or conditioning tower, located in front of the dedusting unit. The neutralization of acid gas starts at the injection point and continues down to the filter.

Semi-Dry Flue Gas Cleaning (FGC) consists of the injection of hydrated lime (Ca(OH)2) into the flue gas at the entry of a reactor or conditioning tower, located in front of the dedusting unit. The neutralization of acid gas starts at the injection point and continues down to the filter.

The latest systems improve performance and decrease the amount of sorbent required due to the use of a conditioning tower or reactor. Some processes are based on an intense recycling rate and others increase the humidity to boost a reaction. Both actions occur in this tower.

The reactor or conditioning tower allows:

- Optimization of the mixing between sorbent & pollutant

- Increased contact time

- Increased humidity of the flue gases (by water injection)

- Control of the flue gas temperature (by water injection)

- Optimization of reagent utilization (by residue recycling)

The performance of these systems depends on:

- the flue gas characteristics such as composition, temperature and humidity

- the quality of the hydrated lime used as a sorbent

- The recirculation rate used in the process

- The use of an activation process for the recirculated by-product

Key benefits of semi-dry FGC with CleanCalco®

- Ready-to-use reagent

- Efficient process

- Low footprint and low maintenance

- Dry by-product & no liquid treatment requirement

- Flexibility

- Large range of flue gas characteristics

- Compatible with every particulate collector

Product range

While these processes originally only used a standard sorbent, recent experience demonstrates a perfect synergy between premium sorbents and some recycling processes. Consequently, Carmeuse developed a full range of calcium hydroxide (or hydrated lime) products in order to adapt to the different conditions.

- CleanCalco® SD (hydrated lime ready-to-use),

- CleanCalco® FGC (hydrated lime ready-to-use),

- CleanCalco® HSF (hydrated lime ready-to-use),

- CleanCalco® CDS. (quicklime for on-site hydrate production)

- CleanCalco® HSF-AC (hydrated lime containing activated carbon ready-to-use),