Wet limestone systems are well established in some sectors such as the Power Generation industry. This process is based on the large degree of contact between the circulating slurry and the flue gases. This slurry circulates in the absorber tower (or scrubber) to neutralize the condensed flue gas pollutant, mostly SO2. The pH of the slurry is a key parameter to be monitored as it drives the entire system and is controlled by the addition of fresh limestone slurry.

Wet limestone systems are well established in some sectors such as the Power Generation industry. This process is based on the large degree of contact between the circulating slurry and the flue gases. This slurry circulates in the absorber tower (or scrubber) to neutralize the condensed flue gas pollutant, mostly SO2. The pH of the slurry is a key parameter to be monitored as it drives the entire system and is controlled by the addition of fresh limestone slurry.

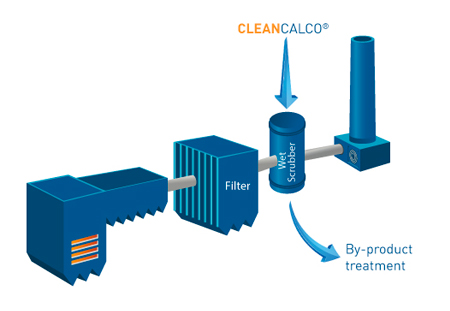

Part of the scrubber slurry has to pump out of the circulating slurry to remove the residues from the system. Several physical and/or chemical treatments exist.

The most used consists in an oxidation system installed at the bottom of the absorber to increase the calcium sulfate production (Calcium sulfite → Calcium sulfate). This low soluble calcium sulfate, also called FGD-gypsum, is removed from the slurry via hydro-cyclone and/or belt vacuum filtering. This FGD-gypsum can be marketable wallboard grade gypsum if the system is designed for this purpose and if the calcium carbonate used as the reagent is pure and reactive enough. Typical companies interested in FGD-gypsum grade are plaster/wallboard producers and cement producers.

Performance of such systems depends mainly on:

- the quality of the limestone used: chemical (purity) and physical properties (particle size, reactivity, hardness…)

- the design and the quality of the equipment

The reagent preparation is a critical step because non-optimum slurry can lead to lower removal efficiencies than the design values and can generate major operating issues. Using ready-to-use micronized limestone gives our customers the greatest confidence in terms of quality control because outsourcing the reagent preparation ensures full adherence to all required parameters. This approach provides far better quality adherence than being sourced with lump stone which puts the quality responsibility on the plant operations and limits quality control.

Key benefits of wet systems with CleanCalco®

- Use of cheap sorbent, limestone

- Marketable/saleable by-product (wallboard-quality gypsum)

- Wet process offers higher contact between reagent and flue gas

- Well-known process, many engineering firms able to design FGT unit

Product range

CleanCalco® LS is our product range designed to fit every customer/engineering specification (milled or lump) for wet FGC. We strongly advise you to plan and design your FGC process in close cooperation with a reagent supplier such as Carmeuse in order to optimize the entire process.

Key applications

Heat & Power Generation

Waste to Energy, often combine with other processes or as multi stage wet process