Power plants that must meet ultra-low emission limits have two choices: switch to lower-sulfur fuels, which add significantly to costs, or implement advanced SO2 removal technologies. The latter is generally the preferred option, but can entail added capital and operating costs, as the following options demonstrate:

Power plants that must meet ultra-low emission limits have two choices: switch to lower-sulfur fuels, which add significantly to costs, or implement advanced SO2 removal technologies. The latter is generally the preferred option, but can entail added capital and operating costs, as the following options demonstrate:

- Addition of an organic additive to the slurry of a wet limestone system: This process requires additional reagent—at additional cost—and makes the wastewater discharge more complex and more expensive to treat.

- Increased slurry volume in circulation: This option increases contact with the flue gases, but calls for a bigger, more expensive scrubber, possibly even dual scrubbers, and extra slurry pumping capacity, which means higher operating costs.

Magnesium-Enhanced Lime (MEL) or (Thiosorbic®) process for ultra-high sulfur removal is a process developed by Carmeuse engineers more than 40 years ago and perfected over the years. The MEL solution is now in place in more than 30 power plants in the United States, generating an excess of 16,620 MW of electricity annually.

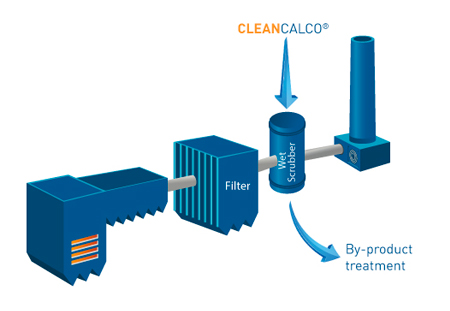

The key to the Carmeuse MEL flue gas desulfurization (FGD) process is the use of a highly alkaline scrubbing liquid, which contains soluble magnesium sulfite. This reagent allows for ultra-high removal rates of SO2 from the flue gases. The MEL FGD system can be operated with a high degree of reliability, because the scrubbing liquid contains less than 100 ppm of dissolved calcium ions, which in turn reduces undesirable gypsum scaling.

By-Product Utilization

By treating the recovered slurry, FGD-gypsum can be produced to Euro FGD-gypsum standards. The result is a useful by-product suitable for wallboard manufacturing.

The Sulfur Capture Reaction

The heart of the Carmeuse MEL FGD system is the addition of soluble magnesium, which produces the following reactions.

Capture of Sulfur by Magnesium Sulfite:

SO2 + H2O → HSO3- + H+

HSO3- + H+ + MgSO3 → Mg(HSO3)2

Regeneration of Magnesium Sulfite:

Mg(HSO3)2 + Mg(OH)2 → 2MgSO3 + 2MgSO3

Mg(HSO3)2 + Ca(OH)2 → 2CaSO3 + MgSO3

Key Benefits

Carmeuse's MEL process offers ultra-high FGD efficiency (more than 99% removal of SO2), at a lower capital cost and reduced operating expense. This process provides users with reliable, proven technology and the Carmeuse assured availability of reagents for all FGD applications.

The advantages of using Carmeuse's MEL process compared to traditional wet-limestone desulfurization include:

- Lower slurry recirculation, which means less pumping capacity is needed, as well as lower slurry sump and thus less capital investment.

- Easier start-up and faster reaction to load changes because magnesium acts as a buffer in the reaction.

- Production of cleaner, more purified FGD gypsum.

- Higher reagent utilization which results in absolute minimum reagent consumption and costs.

- Lower scaling potential

Product range

CleanCalco® MEL is our quicklime containing the right amount of magnesium to suit the MEL process requirement perfectly.